- KLINGER Australia

- Integrity Services

- Asset Integrity

- Leak Risk Integrity Survey

Related Services

- Passing Valve Survey

- Steam Trap Survey

- Compressed Air Integrity Survey

- Insulation Containment Survey

- Flame Ionisation Detection

- Optical Gas Imaging

- Ultrasonics (Airborne)

- CIMS Database

Have any queries?

Get in touch

Call 1300 798 279 (from Australia)

+61 8 9251 1600 (outside Australia)

OR send us your enquiry

Leak Risk Integrity Surveys

Leak Risk Integrity Surveys can be conducted during different phases of a plants’ operation to assess potential and existing leak risks.

KLINGER Atmeco offers various ways to deploy this survey, to take a proactive approach towards mitigating leak risks.

This survey can be conducting during normal operations, prior to a planned shutdown, during start-up or as an all-encompassing workflow for complete shutdown leak management.

View the leak risk integrity survey options below.

Continuing Leak Survey

A continuing leak survey is a periodic, structured and prioritised assessment of an operating plant based on hybrid survey methodologies. Surveys are designed to detect failed sealing integrity on components, lines & vessels during normal operations.

This type of survey uses three non-contact leak sensing technology methods simultaneously – a Flame Ionization Detector (FID), Optical Gas Imaging (OGI) and Airborne Ultrasonics.

Often deemed a regulatory or corporate management requirement, this type of survey is part of an overall and continuing site risk management program.

Pre-shutdown Leak Survey

Pre-shutdown surveys are conducted prior to a planned shutdown to help identify and plan for facility integrity actions and leak remedial work that will need to be completed during a shutdown.

This survey is designed to find leaks from any source using Optical Gas Imaging (OGI) and/or Flame Ionization Detector (FID) technology.

Startup Leak Survey

At the earliest operational opportunity, startup leak surveys are conducted on line, vessels and components at their typical working temperature and pressure. This assists to manage start-up risk and also review existing scope of shutdown work integrity.

Utilising our Component Integrity Management System (CIMS), KLINGER Atmeco can conduct pressurised inert gas surveys, typically using compressed air, helium tracer gas or nitrogen. Leaks are detected during the air and nitrogen purge phase of a start-up and repaired before proceeding to the hydrocarbon introduction phase. Ultrasonics technology Optical Gas Imaging (OGI) and/or Flame Ionization Detector (FID) technology are typically used during start up leak surveys.

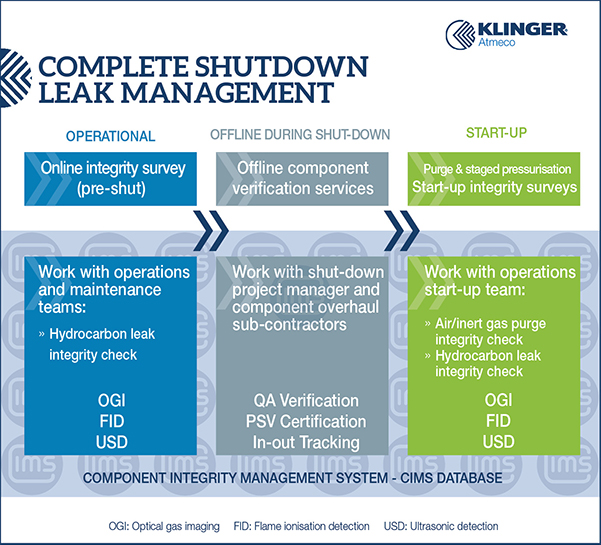

Complete Shutdown Leak Management Approach

Includes surveys conducted prior to a planned shutdown, during a shutdown and during start-up for total leak prevention. The diagram below shows the key steps and components of this workflow for complete shutdown management.